This quarter we reflect on the floods that have devastated our community and the timely release of the International Panel on Climate Change (IPCC) 6th Assessment Report

This quarter we reflect on the floods that have devastated our community and the timely release of the International Panel on Climate Change (IPCC) 6th Assessment Report

International Panel on Climate Change

The International Panel on Climate Change (IPCC) is a global organisation of scientists responsible for monitoring and assessing climate change. Established in 1988 they publish assessment reports every 5 years and have recently released the 2nd part of the 6th report that focuses on climate impacts, vulnerability and adaptation.

The recent assessment report is the most comprehensive to date with over 7 years of peer reviewed science.

The first part of the report published in 2021 focused on projections for future warming and impact on climate systems. The second part specifically assesses the impact of climate change on human communities, ecosystems and biodiversity and what adaptations are necessary through examining the source of emissions from all aspects of society.

The key finding is that Greenhouse gas emissions need to be reduced by 45% by 2030 and net zero by 2050 to ensure temperatures don’t raise above 1.5 degrees Celsius in line with the Paris Agreement.

However, we are on a trajectory for a catastrophic temperature raise of above 2 degrees Celsius due to inadequate action being taken on a global scale.

We are already witnessing the destructive impacts of 1.2 degrees warming pre-industrial levels from the wild fires of 2019-20 to the still very raw recent flooding that devastated our community. These humanitarian disasters are unprecedented and the incompetence of the government to provide support to those impacted has clearly demonstrated inadequacies. It was the communities on the ground running rescue operations and providing support to victims of the floods.

There needs to be acknowledgement and accountability. Investment and support to rebuild with resilience.

Ending coal is said to be the single most important step to end our global addiction to fossil fuels. Our economic model must change and there is opportunity with an abundance of natural resources. We have the solutions, it is within our capacity to solve this crisis.

If action isn’t taken our economic, national, food and water security are threatened. Our physical safety and mental and emotional health, we are facing an epidemic of eco-anxiety particularly in our youth.

Sea level raises pose a very real existential challenge to Torres Straight and other low lying coastal communities.

It is the most vulnerable that are at risk both within our communities and the Global South. The Global North is responsible for 79% of global emissions and yet it is the Global South that are already suffering the impacts of climate change.

It is the youth driving grass roots direct action challenging the misinformation, greenwashing and propaganda we face.

Every action has a reaction

There is a sense of urgency, this is the decade of action and mitigation. Our decisions will forge pathways that will define the future of our planet. Collectively we need to change our narrative and culture.

Every action we take and decision we make as individuals can inform change. Let’s stand in solidarity and take collective action.

So, how can we act as individuals? This quarter we collaborated with Carbon Positive who have developed a carbon calculator. To kick off the year we launched a Carbon Challenge with some amazing tips on how to reduce your impact. Read these blogs for practical tips and tricks to reduce your personal carbon emissions:

- Power, Banks & Super – Why divesting is one of the most important changes you can make - Read here

- Food & Waste, Carbon & Consumption - Read here

- Travel & Transport - Read here

- Water - Read here

Other actions you can take:

- Become part of a climate activist group

- Lobby the government

- UN act now campaign, click here for more info

Community Spirit tee

In response to the devastation of the recent floods we offered our community the opportunity to design an artwork for a charity tee to raise money to support those affected.

100% of the profits made from the sale of our Community Spirit Tee will go towards supporting our flood affected community. You can purchase yours here

Made in Australia

This quarter 19% of our garments were manufactured here in Australia. We believe in the importance of localisation. By manufacturing in Australia not only are we reducing carbon emissions from transportation but supporting our community, industry and economy. Haven was made by an Ethical Clothing Australia (ECA) certified Melbourne based factory.

There are of course challenges to manufacturing in Australia in terms of limited supply chains and higher price point. The cost of manufacturing is higher relative to our economy and wages. By paying more for beautifully crafted quality garments we can foster a deeper appreciation and value, and consume less.

Natural dyes

This quarter we launched our first naturally dyed collection. Sugar was dyed using natural dyes derived from by-products.

The pigment used to dye the Canyon Sugar is made from 90% bitter orange and grapefruit extract residues. These extracts are flavonoids used as antioxidants in the pharmaceutical industry.

Closing the loop, reducing waste, resource depletion, water and chemical pollutants.

Reference: Sustainable Apparel Coalition, Higg Material Sustainability Index (Raw Materials).

We are unable to report on BCI cotton as there is currently no data available in the Higg MSI.

Freight

Due to unforeseen delays and the impact of further lockdowns in our supply chains we had to resort to air freighting. We are dedicated to moving to a sea freight model through careful planning going forward.

Circularity

By utilising deadstock for our collaboration with Mother the Mountain we saved 430m from landfill.

Let's start with some reflections and highlights from the last three months of 2021.

Combatting Overproduction

“However ambitious, fashion’s environmental efforts are all for naught, say critics, if the industry doesn’t also address its overproduction problem, which they say is the underlying driver of its mammoth carbon, water and waste footprints.” - Vogue Business, Fashion’s sustainability agenda: Where to start

One of our favourite highlights from Q2, 2021 was launching Freya, our first Made To Order collection. We recognised our contribution to one of fashion’s biggest problems – waste via overproduction. With continually evolving demand, we saw we were sitting on more stock than our consciences could handle as a sustainable brand. So, we took action to work towards changing our business model in order to create less waste by launching our Made To Order collection, Freya.

Deforestation & Leather Choices

The fashion industry is complicit in the destruction of the Amazon Rainforest, another reason why we are passionately obsessed with LENZING™ ECOVERO™ and continue to explore conscious fibre choices that are better for our people and the planet.

“For viscose, which has been associated with heavy deforestation, brands can start making the switch to sources of viscose that are made from recycled clothing or food waste, which uses 90 per cent less water, 75 per cent less energy and greener chemistry than forest based viscose, notes Rycroft.”

We launched two new belts made from 100% LWG certified leather. Learn more about Leather Working Groups traceability efforts for combating deforestation in the leather industry here.

Greenwashing, what does it mean?

As climate change becomes an undebatable mainstream issue, brands are going to do everything in their power to ensure people continue to shop with them. This can be a good thing, meaning brands change their strategies in order to meet consumer demand by creating ethical products. On the flip side it can also mean marketing and product team will do whatever they can to keep up with consumer sustainability preferences on a surface level. This means offering little to no substance underneath the flashy products, ads, and marketing.

This is where the term greenwashing comes in.

Greenwashing is the process of conveying a false impression or providing misleading information about how a company's products are more environmentally sound. Greenwashing is considered an unsubstantiated claim to deceive consumers into believing that a company's products are environmentally friendly. – Investopedia

Some of the biggest brands are the worst culprits of greenwashing behaviour and it isn’t just the fashion industry. There are no regulations in the beauty industry for naming your brand with terms like organic, clean, eco, etc. For example, if the brand name is ‘Simple’ and the look and feel is earthy with leaves in the logo, it makes sense to assume this is an eco-friendly or clean brand. More often than not, when you look at the ingredients, the branding is creating an impression of ‘ethical and healthy’ but the products are full of nasty chemicals.

Well, the same is for the fashion industry.

Fast-fashion brands are some of the worst culprits, hopping on the sustainability bandwagon in order to keep profits growing without truly offering sustainable or ethical products.

Changing Markets Foundation found that, “Ninety-six percent of claims that H&M made to promote Conscious were misleading and fake. Instead of their clothing being produced from 100% organic cotton, only 20% of it actually was organic cotton because “it wouldn’t have the same quality.” Under Conscious’ section on H&M’s website, it never stated where the materials were sourced.” — Sydney Race, The Central Trend, Companies are lying to us by greenwashing their products

Changing Markets Foundation also revealed in their report that of the brands who made sustainability claims in their products, 60% of these big brand’s sustainability claims were false or unsubstantiated. Some of the brands included in this study were; Asos, Boohoo, Forever 21, George at Asda, Gucci, H&M, Louis Vuitton, Marks & Spencer (M&S), Uniqlo, Walmart, Zalando and Zara.

We know we’re not perfect, but reporting each quarter on our efforts is a step towards transparency and a more ethical fashion industry.

Here’s a snapshot of our reduced environmental impact this quarter…

Climate change is, and always will be, a hot topic. To survive rising temperatures every system in the world, natural or human, will need to be as strong and healthy as we can make it.

For this Q1 2021/22 Impact Report we are focusing on COP26 - the world’s opportunity to deliver a credible, binding response to the climate disaster we currently face. And, we are highlighting our industry's impact, and what we are doing to take responsibility.

So what is COP26 about?

Conference of the parties, otherwise known as COP is an annual global United Nations climate conference attended by our world leaders. COP26, the 26th annual conference postponed in 2020 due to Covid-19, is currently being held in the UK in Glasgow with 196 world leaders attending. Here they unite forces to tackle climate change and accelerate action towards achieving the Paris Agreement climate goals made back in 2015 at COP21. At COP21 every country agreed to limit global warming to 1.5 degrees Celsius of pre-industrial revolution levels, with a reduction of 45% carbon emissions by 2030.

Alas, we have seen an increase in carbon emissions since the agreement was made and have subsequently witnessed devastating and unpredictable climate chaos from drought and wildfires, to extreme storms and flooding events.

Threatening our very survival. There is a sense of urgency and need for solidarity.

It is reported that the global temperature rise has already exceeded 1 degrees Celsius and more than one fifth of all human populations live in regions that have experienced a raise of 1.5 degrees Celsius. On the current trajectory global warming could increase by 4 to 5 degrees Celsius by the end of the century - this would be catastrophic.

There's no denying the science.

There have been intense discussions at COP26. These are just some of the highlights:

- More than 100 world leaders promise to end and reverse deforestation by 2030.

- 100 countries have pledged to cut emissions of the greenhouse gas methane by 2030.

- 40 countries have committed to shifting away from coal (not Australia!).

But, these strategies only form part of the solution. We need to transition to a circular economy, moving away from the current take, make, waste economic model. Redesigning products and services that eliminate waste and emissions by keeping resources in the value chain within industry, land use and agriculture. This will require innovation, financial investment and systemic infrastructural change through government policy.

So is there hope?

As individuals we can make a difference through lifestyle changes that can help the plight of our planet; shop locally, consume less meat, recycle more, take public transport. However, this is not enough, we need to lobby our government to take action. They have the power to change policy and stop the destruction and pollution of our precious planet.

“If working apart we are a force powerful enough to destabilise our planet, surely working together, we are powerful enough to save it.” ~ David Attenborough, COP26 2021.

Fashion's Impact.

A 2020 report found that the Fashion industry’s emissions are actually set to rise to around 2.7 billion tons a year by 2030, if current measures stay the same. Fashion’s emissions would be at double the maximum level required to be in line with the Paris Agreement’s aim to keep global warming to 1.5°C.

But in other news... we now have a shiny new number for how polluting the fashion industry is: 2% of global greenhouse gas emissions. That's a huge drop from the original 10% figure frequently cited - a number that some UN intern made up a decade ago.

The new 2% number is courtesy of The World Resources Institute and the Apparel Impact Institute, which recently co-released a new report. They used Higg and Textile Exchange data to come up with 1.025 gigatonnes (Gt) of carbon dioxide equivalent (CO2e) released as a result of fashion in 2019.

"Unchecked, emissions will grow to 1.588 Gt by 2030, well off pace to deliver the 45 percent absolute reduction needed to limit warming to 1.5°C," the report said.

What are we doing?

There’s a lot of work ahead of us to become truly sustainable and we are committed to being honest, transparent, and taking responsibility for our actions. We are trying to stay in line with the Paris Agreement emissions reductions targets. This quarter, we are looking to expand our carbon emission reduction targets as a business and setting our goals for the year ahead.

Our challenge.

One of the biggest challenges we face as a company, and as an industry is visibility through our entire supply chain.

Our commitment.

In July 2020, we set the target to reduce the carbon emissions from our freight by 45% by 2025 in line with the Paris Agreement.

Our goal for 2021-22 is to introduce environmental auditing with our key Tier 1 suppliers, expanding our emissions reporting through our supply chain. We will continue to report on freight emissions and will also review emissions generated by our store, head office and distribution centre.

This visibility will allow us to develop a more targeted strategy for carbon off-setting. The environmental auditing will also provide an insight into our Tier 1 supplier water consumption and waste water treatment, which is another critical issue.

The introduction of made to order collections is another exciting sustainable strategy. It is reported that the fashion industry is responsible for 92 million tonnes of solid waste annually. 30% of clothes made remain unsold as deadstock.

Fast fashion is a relatively new phenomenon. This faced paced instant gratification fuels a disposable mindset. Traditionally clothes were made to order; the anticipation fostering a deeper appreciation. We believe designing classic timeless pieces using a made to order model offers a slow sustainability solution to reduce textile waste, resource depletion and carbon emissions.

Additionally we are introducing an exciting new initiative to move towards a circular fashion economy: watch this space!

Our goals for 2021-22 in line with the Paris Agreement emissions reductions targets.

- Introduce environmental auditing and emissions reporting for key tier 1 suppliers by the end of 2021-22.

- Expand on emissions reporting for our distribution centre, head office and boutique.

- Carbon off-setting through donations and collaborations with our partners in line with our carbon emissions.

- 90% of orders to ship by sea freight.

- Made to order collections.

Here's a snapshot of our Q1 2021/22 Performance.

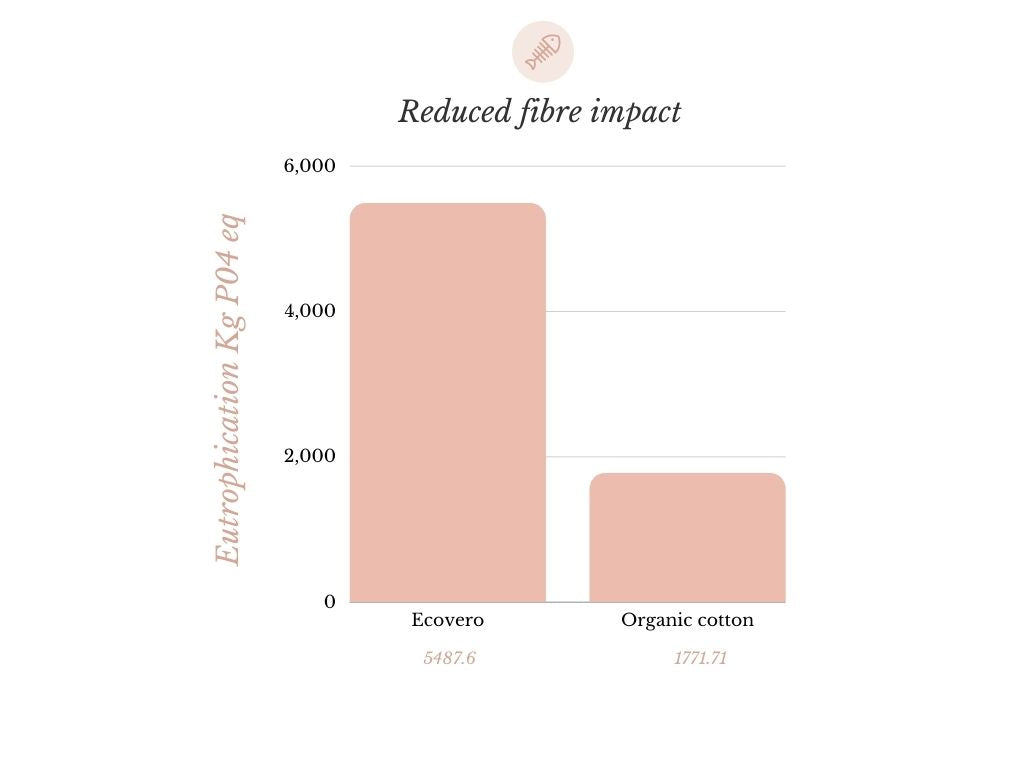

Reduced fibre impact.

By using sustainable fibres in place of generic fibres we have reduced our impact by:

Reference: Sustainable Apparel Coalition, Higg Material Sustainability Index.

Want to decode the above? Head on over to our glossary of sustainability terms here.

Circularity: Revive.

To meet the UN targets we need to transition to a circular economy, moving away from the current take, make, waste economic model. Redesigning products and services that eliminate waste and emissions by keeping resources in the value chain.

This quarter, we have repurposed most of the waste fabric from landfill to craft our Dylan Revive Scrunchies and Headbands, launching soon!

We are expanding our Revive offering, collaborating with local designers and makers…stay tuned for more...

So Extra.

We’re proudly extra! We avoid plastic at all costs – no plastic packaging, trims as in buttons and zips, or kimbles. We use exclusively FSC recycled materials for packaging and swing tags. We keep it it all compostable.

There’s a lot of work ahead of us to become truly sustainable and we are committed to being honest, transparent, and taking responsibility for our actions. We’re forever grateful to you for joining and supporting us on this journey.

We are excited to present our first ever zine. Our first ever Sunday Sustainable - Annual Edition. Wildly delayed but our team hustled to pull together amidst lockdowns and pandemic mayhem but - this too feels like the new norm.

In a world that feels a little dark, we are proud to celebrate the achievements you helped us reach, reiterate our commitment to sustainability and transparency.

Thank you for being a part of our journey.

Prefer Reading the real deal?

We will have a limited run of printed copies available next week

DOWNLOAD A COPY

For us, sustainability is a lifelong journey, and our ultimate goal is to be able to create from a place where all life forms and future generations can flourish, and ecosystems can recover and become resilient. But just like you, we’re only human, so we focus on consistent progress, rather than perfection. We want you to trust that what you buy makes a difference, so this quarterly report is proof of our commitment to being transparent and accountable.

You will find facts and info about all areas of our business below, however we’re super excited to share the serious progress we’ve made this quarter across all sustainability pillars. We hit a major milestone when it comes to the pillar of people, by manufacturing our first ever collection here in Australia! A significant climate action goal for us was making the switch from air freight to road freight as a standard option for delivery of your treasures within Australia – and we can’t wait for you to read about the impact on our planet below! And when it comes to profit, this quarter with the launch of our globetrottersiraconlineusa X Rainforest Rescue ‘It’s In In Our Hands’ charity tee through our giving back program, together we have planted 383 trees.

So, cosy up and get stuck into this quarters must-read...]]>

We talk a lot about sustainability; but what does it really mean?

We talk a lot about sustainability; but what does it really mean?

For us here at globetrottersiraconlineusa we define it as the processes and actions we take to avoid the depletion of natural resources, in order to keep an ecological balance and allow good quality of life for all who inhabit our planet.

When measuring our impact and looking for opportunities to do better we focus on three sustainability pillars: people, planet and prosperity.

Sustainability is a lifelong journey, and our ultimate goal is to be able to create from a place where all life forms and future generations can flourish, and ecosystems can recover and become resilient. But just like you, we’re only human, so we focus on consistent progress, rather than perfection. We want you to trust that what you buy makes a difference, so this quarterly report is proof of our commitment to being transparent and accountable.

You will find facts and info about all areas of our business below, however we’re super excited to share the serious progress we’ve made this quarter across all sustainability pillars.

We hit a major milestone when it comes to the pillar of people, by manufacturing our first ever collection here in Australia!

A significant climate action goal for us was making the switch from air freight to road freight as a standard option for delivery of your treasures within Australia – and we can’t wait for you to read about the impact on our planet below! And when it comes to profit, this quarter with the launch of our globetrottersiraconlineusa X Rainforest Rescue ‘It’s In In Our Hands’ charity tee through our giving back program, together we have planted 383 trees.

So, cosy up and get stuck into this quarters must-read...

Beneath Our Sun: First ever Australian Made Collection

This quarter we launched our first made in Australia collection. We are extremely excited to be supporting local makers and hope to have seasonal collections made in Australia going forward.

Our “Homegrown” tee was knitted and manufactured in Melbourne. With a mill established in the early 90’s ABMT are a vertical operation combining fabric knitting and garment manufacturing. This efficient centralised system offers quick response to market as well as minimising fabric waste and ensuring quality control.

The organic cotton was grown and processed into yarn in India. Growing organic cotton in Australia is unfortunately uneconomical. We are currently exploring Australian grown cotton practices as this would be the ultimate sustainable tee dream.

ABMT are pioneers of ethical and sustainable manufacturing here in Australia. Their facility is predominantly solar powered and their 5 stage on site water treatment plant allows for up to 85% of water to be reused through the manufacturing cycle or by a 3rd party program for agriculture and industry.

Their fabrics are Australian certified organic and manufacturing is Ethical Clothing Australia certified. Their strong ethos for transparency, ethical and environmental responsibility and quality are inspirational.

ABMT production manager interview

What is your name?

Parveen Abusalam

What is your job role at ABMT?

Production manager

How long have you worked in the fashion industry?

25 years

What inspired you to work in the fashion industry?

The love of fashion, meeting new people, travel

What do you like about working at ABMT?

The people I work with are extremely nice and have a good work life balance

What do you like to do in your spare time?

Like going for long walks, catching up with friends

Our woven collection was crafted by Lux Design Group in Melbourne. With a longstanding relationship with Ethical Clothing Australia certified manufacturers their community values are very much in alignment. They offer strong attention to detail and were able to skilfully navigate our complex designs and border placements. We were delighted with the quality and look forward a blossoming relationship. The fabric for this collection was woven and printed in China as we were unable to source within Australia.

We trust that through supporting the industry here we can help facilitate its growth and expansion. With a very limited woven apparel textile industry increased demand will drive innovation and technology. Economies of scale will support accessibility of price point necessary to compete in the global market.

Lux Design production manager interview -

What is your name?

Ba Phan

What is your job role?

Production manager

How long have you worked in the fashion industry?

I have worked in the fashion since 1998, so for 23 years

What inspired you to work in the fashion industry?

My first job in Melbourne was in the fashion industry and I have worked in the same industry ever since. My family also worked in this industry so growing up, I had a lot of experience in this area.

What do you like about working at Lux?

Lux has a diverse range of styles that would be appealing to customers. Some styles are new and different, which I prefer.

What do you like to do in your spare time?

My hobby is gardening. On the weekends I tend to my plants and flowers both indoors and outdoors.

| Fiber | Percentage % | Fibre Category |

| Hemp | 1 | Heros |

| Lenzing Ecovero | 55 | Rising Stars |

| Organic Cotton | 36 | |

| Recycled Nylon | 1 |

99% of the fibres used this quarter were sustainable

By using sustainable fibres in place of generic fibres we have reduced our impact by:

| Fiber | Global Warming Kg Co2 | Eco-toxicity Kg P04 eq | Water Scarcity Gallon | Abiotic resource depletion MJeq |

| Lenzing Ecovero in place of generic viscose | 9,745.99 | 8,228.36 | 1,227,797.71 | 7137.57 |

| Organic Cotton in place of generic cotton | 1,366.4 | 9,342.59 | 15,116,323.7 | 688.43 |

| Recycled Nylon in place of generic nylon | 185.96 | 28.7 | -932.52 | 255.41 |

| Total | 11,298.35 | 17,599.65 | 16,343,188.89 | 8061.41 |

The process of mechanically recycling nylon unfortunately requires more water than generic fossil fuel-based nylon however the reduction in greenhouse gasses, eco-toxicity and resource depletion off-sets this.

Reference: Sustainable Apparel Coalition, Higg Material Sustainability Index.

We have not included our sustainable cotton corduroy and denim collections as BCI cotton reporting is not available on the Higg MSI tool at this stage. We will look to review this once this data is available.

We have saved the following plastic bags from landfill by introducing compostable packaging:

This quarter we launched our latest charitable tee “It’s in your hands”. The profits made from the sale of the tee will support the restoration of the Daintree Rainforest through a joint project of Rainforest Rescue together with Eastern Yalanji Traditional Owners and their representative corporation, Jabalbina, Greenfleet, and the Queensland Trust for Nature with the goal to plant ONE MILLION RAINFOREST TREES within 5-10 years.

This incredible project will provide habitat, sustain ecosystems and sequester carbon.

To date we have raised $3,833.22

This quarter we introduced a standard domestic freight option for our online customers. We pride ourselves on our service and ensure customers receive their treasures in a timely manner. After reporting on our carbon emissions for the last few quarters we realise that the express service is significantly contributing to our carbon footprint. We hope you will support us and opt for standard freight shipping and look forward to reporting on the reduction in carbon emissions in the next quarter.

]]>Transparency matters, because we want you to trust that what you buy makes a difference. Sustainability is at the core of everything we do, because we care about the health of people, planet and future generations.

In the second quarter of 2020/21 we were tracking at 99% sustainable fibres, saving 58,404 plastic bags from landfill, off-setting enough carbon to be carbon neutral for domestic & international freight, and continuing on a mission to be circular by design. But from previous reports you know that we’re already scoring well in these areas. So, this quarter we are honing in on social sustainability by introducing you to our Artisan family.

We are devoted to expanding opportunities in some of the most vulnerable countries by addressing inequality, protecting the planet and working to ensure prosperity. When you purchase an Artisan made treasure, you are conserving traditional knowledge and positively impacting lives of future generations around the world. We are also shining the spotlight on supply chain transparency, which is critical to ensure protection of workers at every stage of production. Trust us, there’s some seriously good stuff in this report, so sit back, dive deeper and find out more about the progress we’re making.

]]>Transparency matters, because we want you to trust that what you buy makes a difference. Sustainability is at the core of everything we do, because we care about the health of people, planet and future generations. In the second quarter of 2020/21 we were tracking at 99% sustainable fibres, saving 58,404 plastic bags from landfill, off-setting enough carbon to be carbon neutral for domestic & international freight, and continuing on a mission to be circular by design. But from previous reports you know that we’re already scoring well in these areas. So, this quarter we are honing in on social sustainability by introducing you to our Artisan family.

We are devoted to expanding opportunities in some of the most vulnerable countries by addressing inequality, protecting the planet and working to ensure prosperity. When you purchase an Artisan made treasure, you are conserving traditional knowledge and positively impacting lives of future generations around the world. We are also shining the spotlight on supply chain transparency, which is critical to ensure protection of workers at every stage of production. Trust us, there’s some seriously good stuff in this report, so sit back, dive deeper and find out more about the progress we’re making.

| Artisan accessories |

This quarter we launched a new range of artisan made accessories. We believe in the importance of protecting and preserving traditional crafts, intrinsically interwoven with culture and history through generations. Empowering marginalised communities socially and economically. Respecting and valuing cultural heritage, capturing unique cultural richness and authenticity. Our range was made from natural materials sourced locally by artisans with minimal impact on the environment.

We wanted to share the stories of the artisans that made the collection with you. Let’s meet the makers:

What is your name?

Bunga Talya Quamilla

Where did you grow up?

In Cirebon, west Java.

From whom, or how did you learn your craft?

I learned to make the crafts from my mother, by watching her making the crafts like bags, accessories, key hangers, etc.

How has partnering with overseas brands to collaborate on artisan products helped your community?

I’m very pleased and proud to work with overseas brands for the items. This will boosts the spirits of the workers as well to support and grow the local group of artisans here and hopefully can accommodate more artisans to work with.

What is a regular day like for you?

I started the day by praying for the day, then start working at workshop making the items or buying material stocks for the workshop in the area. On the night time I’m preparing the package and deliver to the local courier in the area to the customers.

What does sustainability mean to you?

For the material terms it is to use materials which are environmental friendly. In related to the business is to keep the business alive to provide the workers by maintaining the quality of the items and developing new styles for the items.

What is your name?

Adis

Where did you grow up?

Kalumpang village, Kapuas, in the province of Central Kalimantan

From whom, or how did you learn your craft?

From my parents. It is mainly a woman's role, the wives spend a long time at home, tending the farms and collect rattan skins, slice and dry them while taking care of children. The learning is taught to young girls when they are 10-13 years old.

How has partnering with overseas brands to collaborate on artisan products helped your community?

From Central Kalimantan, we have to buy materials to Bali on shipment. If the brand sells well, we help the rattan farmers and our weavers, with their income.

What is a regular day like for you?

I live in Bali with my wife and 8 years old son, we have a shop selling rattan-woven handbags, ladies bags, travel bags and some baskets and floor mat - all from my village - Kapuas. I open my shop at 8 and clean around shop, my wife goes to buy supplies and take our son to school (but not anymore with COVID19) we help him with online teaching.

What does sustainability mean to you?

It means we must live without destroying our nature. Our ancestor in our island, Kalimantan - teach us to respect nature and the nature will bring us back our food (that means, we sell our products and the income puts food on the table).

Frida Straw Bag: Launching soon...

What is your name

My team have Charuayporn , Awe Parnsomboon, Lumpon Parnsomboon, Bunjerd Kantuam , Nuntakarn Kantuam my team had 30-40 person for weaving (age period 35-80 years old).

Where did you grow up?

We are local people of Central Thailand.

From whom, or how did you learn your craft?

We learn from grandparents who have been passed down through generations. First, weave bamboo and develop into water hyacinth.

How has partnering with overseas brands to collaborate on artisan products helped your community?

For collaboration with overseas brands, it helps my team meet the standards. And experienced.

What is a regular day like for you?

Weaving this is my main job except for the farming season. On farming season, we have to farm and return to weaving in the evening.

What does sustainability mean to you?

This weave the bag is important for our family. We can weave and take care of our parents, sons or grandchildren. Some families don't have to go to work in the capital. They can work from home. Then we have to teaching children and those interested in the event. Keep this knowledge. We are not afraid of the coming of machines product. Because that makes this craft product an interesting place.

What is your name?

My team have Somjit, Prachya , Tuenjai , Noon , Sompong, Boonyang, Thongdang my team had 20-30 person for weaving (age period 30-70 years old)

Where did you grow up?

We are local people of Northeast of Thailand

From whom, or how did you learn your craft?

We learn from grandparents who have been passed down through generations. First, weave basket with water hyacinth and develop into slippers

How has partnering with overseas brands to collaborate on artisan’s products helped your community?

We are proud to cooperate with global brands and hope my products will make more people to know. And hope my local has more orders and revenue.

What is a regular day like for you?

Regular day, we weave slippers and grow vegetables. If we have a lot of orders we have to divide the team. Men grow vegetables and women weave slippers.

What does sustainability mean to you?

Water hyacinth is a weed and a sustainable fashion. These slippers can massage and save the world. We will continue to teach the local children to maintain this knowledge.

| We have a strict code of conduct in place. 100% of our Tier 1 suppliers (garment manufactures) have signed our Code of Conduct |

|

| Percentage by fibre category | |

| Heroes 4% | Lenzing Tencel, Linen, Hemp, Revive - fabric off-cuts |

| Rising Stars 95% | Lenzing Ecovero, Organic Cotton (GOTS), Mechanically recycled nylon, Econyl |

| Work in Progress 1% | Other: Polyester and elastane |

| 99% of the fibres used this quarter were sustainable |

By using Econyl in place of generic nylon we have recovered 66.70kg of waste including 16.6kg fishing nets from the ocean

| By using sustainable fibres in place of generic fibres we have reduced our environmental impact: | ||||

| Fibre | Global Warming (kg Co2) | Eco-toxicity (kg P04 eq) | Water Scarcity (gallons) | Abiotic Resource Depletion (MJ eq) |

| Econyl in place of genric nylon | 1,745.67 | 269.48 | -8767.86 | 2,397.61 |

| Lenzing Ecovero in place of generic viscose | 27,119.45 | 22,896.55 | 3,416,513.84 | 19,861.27 |

| Organic Cotton in place of generic cotton | 653.24 | 4,466.61 | 7,226,999.7 | 319.56 |

| Recycled nylon in place of generic nylon | 185.75 | 28.67 | -932.52 | 255.13 |

| Lenzing Tencel in place of generic lyocell | 798.1 | 563.5 | 77,711.49 | 365.7 |

| Total | 30,502.21 | 28,224.81 | 12,880,073.39 | 23,199.27 |

The process of mechanically recycling nylon unfortunately requires more water than generic fossil fuel based nylon however the reduction in greenhouse gasses, eco-toxicity and resource depletion off-sets this.

We have saved an estimated total of 12,880,073.39 gallons of water by using sustainable fibres instead of generic fibres.

| Definitions: |

Water is becoming increasingly scarce, due to excessive & unnecessary use and wastage.

Abiotic Resource Depletion

Abiotic depletion refers to the exhaustion of natural (non-living) resources. The main concern is the ecosystem’s health and how it is affected by the extraction of minerals and fossil fuels.

Global Warming (CO2)

Global warming is a serious environmental issue, contributing to the increase in Earth's average surface temperature due to rising levels of greenhouse gases.

Eutrophication (eco toxicity)

Eutrophication is when a body of water becomes overly enriched with minerals and nutrients due to run-off from the land, which causes a dense growth of plant life. This can eventually lead to water bodies that can't support aquatic life.

Abiotic Resource Depletion

Abiotic depletion refers to the exhaustion of natural (non-living) resources. The main concern is the ecosystem’s health and how it is affected by the extraction of minerals and fossil fuels.

| International | |

| Sea freight | 0.36 tonnes of C02 |

| Air freight | 1.43 tonnes of C02 |

| Road freight | 0.58 tonnes of C02 |

| Total | 2.37 tonnes of C02 |

| Domestic | |

| Total | 93.08 tonnes of C02 |

| Total C02 Emissions Q2 2020/21 = 95.45 tonnes of C02 |

Fabric that ends up on the cutting room floor is usually destined for landfill. Our globetrottersiraconlineusa Revive initiative is all about turning fabric off-cuts into beautiful, fabric efficient accessories to match back with your globetrottersiraconlineusa treasures. The idea was inspired by our makers on one of our visits to their factories, we saw our bright floral fabric remnants crafted into pin cushions, scissor lanyards and fabric weights.

This initiative not only allows us to repurpose fabric from waste but also provides more work and income for our makers.

In Q2 we saved around 8,473m worth of fabric offcuts and transformed them into 2075 stunning revive accessories that we know you love. Circularity at its very best.

In the first quarter of this financial year we’ve made positive environmental changes by switching wholly to sea freight to further reduce our carbon emission, focusing our zero-waste initiatives on creating alternatives to single-use plastics, and making our collections from 99% sustainable fibres. With a spotlight on people we are incredibly excited to have welcomed a new maker to our family; a Turkish mill who are pioneers in the sustainable denim industry. And thanks to you, we made huge progress with our social sustainability program by giving back $52,388.32 to The Great Koala National Park.

With sustainability at the forefront of every decision we make, read on to find out how we’ve performed in the first quarter of 2020/21.

]]> What you buy makes a difference and together we are creating change in the fashion industry, by choosing to protect and honour mother earth, and all living beings.

What you buy makes a difference and together we are creating change in the fashion industry, by choosing to protect and honour mother earth, and all living beings.

| We raised an incredible $52,388.32 with the sale of our “for our future” koala tee. |

- GKNP will develop a series of short positive and compelling films about the importance of the Great Koala National Park. These films will be used as a TV advertising campaign in the lead up to the next election. They will also be used on the new website and in the visitor centre. The focus will be Cultural heritage, Conservation, Recreation and Tourism, and Economic.

- Brochures about the GKNP for distribution as part of a broad promotion campaign for the GKNP. These materials will to be sent to stakeholders and supporters.

- Lobbying parliamentary targets in the NSW Government and State Opposition. A group of representatives will travel to Sydney for a series of meetings in the NSW parliament in 2021.

- Help conduct citizen science koala and other key species surveys in priority forest areas so that data can be added to the Bionet atlas.

- Develop a Gumbaynggirr cultural component to the Visitor Centre’s information displays. Including the Koala Story.

- Make a financial contribution to the Gumbaynggirr Cultural Heritage study.

Thank you to all who supported this amazing cause! For more information read this post on our blog.

| Plastic Free July |

Up to 130,000 tonnes of plastic finds its way into our waterways and oceans, harming marine wildlife, polluting the food chain and changing the oceans chemistry, slowing its ability to uptake CO2.

Zero waste living is a core value at globetrottersiraconlineusa, we wanted to develop a range of products to offer accessible and sustainable solutions for Plastic Free July to empower our customers to make conscious choices to minimise plastic consumption and waste. We used fabric off-cuts to create a range of Revive products. We believe strongly in supporting local businesses where possible and in this quarter, we partnered with a number of new Australian brands we love and value to help our customers shop locally and eliminate plastic in our day to day lives.

| Meet Our Collaborators: |

Byron Hinterland NSW

Zero Waste Kulture is an award winning, globally focused, sustainable brand and online community. Their focus is to provide education, connection and opportunities for the environment. Their products reflect this ethos, made from recycled materials produced ethically and sustainably. For Plastic free July we collaborated with Jodee again to create more of our Revive Everyday Household Wipes and Face Wipes.

Byron Hinterland NSW

It is estimated that Australians use 1 billion disposable coffee cups every year, only 1 in every 400 cups is recycled. Hand crafted and individually decorated and glazed, Brooke’s ceramic vessels celebrate space, vitality and imagination. Having collaborated already with Brooke on Keep-Cups and Mugs, we decided to create limited-edition 8oz Ceramic Tumblers for espresso and negroni lovers alike.

Byron Hinterland

Crafted from locally sourced beeswax. Formulated as a personal desire to find a natural alternative to plastic wraps. We love collaborating with Marianni rescuing our fabrics scraps from landfill and reviving them into beautiful, eco-friendly alternatives to cling wrap to create Pre-made & DIY Beeswax Wraps.

Melbourne VIC

Created by a husband and wife duo with a vision to end plastic pollution by developing beautifully designed, incredibly functional and fairly priced reusable alternatives to single-use plastic. Having collaborated on Re-Useable Straws that sold out in minutes, we chose to use our revived fabric to create zero-waste Cutlery Sets and another round of reusable gold stainless steel Straws, each with their own carry pouch for day to day plastic free living.

Byron Bay

Hand poured with natural soy wax and cotton wicks infused with pure essential oils. Their candles invoke the spirit of Byron Bay through the senses and induce holistic benefits of ambient light and aromas. Always in search of minimum waste solutions we launched two new, eco-friendly, non-toxic candles for PFJ, Golden Hours and Tahiti, together with refills so your jars never go to waste.

Manley QLD

Sow n Sow combines a love of gardening and design. We teamed-up for PFJ to create two products crafted in Australia from recycled paper, making the perfect gift for novice gardeners and green thumbs alike, with the hope of inspiring a grow-your-own community, mindfulness and keeping buying local. Discover our Culinary Flower Seeds and Marigolds online.

Bonville NSW

Hand crafted from Fair trade ethically sourced ingredients. Established for 31 years Chai Tea operate on renewable resources and use recycled plastic free packaging - conventional tea bags are often sealed with polypropylene (aka plastic). As a connoisseur of Chai Tea and as a zero-waste warrior it was an obvious collaboration for globetrottersiraconlineusa when she thought about ways to inspire people to reduce single use plastics.

Newcastle NSW

Drawing on ancient plant wisdom and pure botanical sources with an emphasis on high quality sustainable ingredients, we were excited to collaborate on our Serenity Face Mist with Studium Essentials.

Melbourne VIC

Yalu natural perfumes are crafted with ancient methods and therapeutic botanicals from the finest 100% naturally derived absolutes and essential oils that are ethically and sustainable sourced. This quarter we collaborated on our Flora Bohemia natural perfume.

| Plastic Free July at globetrottersiraconlineusa HQ |

The use of poly bags to package garments is a very serious issue contributing to this. It is estimated that 180 billion poly bags are used in the fashion industry annually. These single use bags end up in landfill where they can take up to 1000 years to degrade leaching toxic chemicals into the soil. Or worse still they end up in waterways and eventually the ocean. By switching to a compostable alternative we have saved...

| International | |

| Sea freight | 0.32 tonnes of C02 |

| Road freight | 0.39 tonnes of C02 |

| Total | 0.71 tonnes of C02 |

| Domestic | |

| Total | 61.71 tonnes of C02 |

| Total C02 Emissions Q1 2020/21 = 62.42 tonnes of C02 |

Our ultimate goal is to have full traceability of our supply chains. This means not only social compliance auditing but physically visiting each operation, building relationships and having an understanding of their working environments and processes. We only use certified fibres and fabrics which allows us visibility and assurance that they meet international standards for social compliance however we plan to map and visit our supply chains as part of our sustainability strategy. This process has unfortunately been postponed due to the outbreak of COVID-19.

We have already visited the majority of our tier 1 suppliers and many of our tier 2 however with the introduction of new suppliers this quarter we are yet to visit them all.

| 100% of our tier 1 suppliers have social compliance in place We have visited 63% of our tier 1 suppliers |

| TAYFUN AND NIHAT, Denim and Cord Mill and Maker |

Tayfun and his team are actively involved in the protection and preservation of the environment. During the denim manufacturing they capture CO2 and re-use it in the finishing process, preventing around 30,000 tons of CO2 from being released into the atmosphere every year! Responsible dyeing saves 85% of water in comparison to conventional dyeing. As cotton growing and denim production requires a lot of water, innovation in reducing water consumption is essential.

- Tayfun Akbay

The cotton for our collections is sustainably produced by farmers who care for water, soil health & natural habitats.

Nihat and his team are the garment manufacturing partner that works closely with the sustainable denim mill. Nihat’s manufacturing company has been established for over 30 years, a family business constantly striving for sustainable innovation. They recover and reuse up to 50% of water used in the laundry and have reduced their energy consumption with the implementation of eco-friendly stitching machines with a reduction of 40% and lighting seeing a further reduction of 25%.

| Both our denim mill and maker have BSCI Social compliance auditing in place. Our denim mill is Okeo Tex 100 certified. |

| WILLIAM, Woven Makers |

William's factory has Smeta social compliance auditing in place. His mill is Oeko Tex 100 certified and fabrics are crafted from Lenzing fibres.

| Percentage by fibre category | |

| Heroes 0% | Lenzing Tencel, Linen, Hemp, Revive - fabric off-cuts |

| Rising Stars 99% | Lenzing Tencel Modal, Lenzing Ecovero, Organic Cotton (GOTS), Sustainable cotton (BCI), Mechanically recycled nylon, Econyl |

| Use Sparingly 0% | Leather, Silk and Wool |

| Work in Progress 1% | Elastane and Polyester. |

By using 99% sustainable fibres instead of generic fibres we may have significantly reduced our impact on our environment. The figures below show our impact compared with the impact of generic fibres:

By using 99% sustainable fibres instead of generic fibres we may have significantly reduced our impact on our environment. The figures below show our impact compared with the impact of generic fibres:

| Comparison of our fibres and Generic Fibres | ||

| Environmental Impact | Our Fibre Impact | Generic Fibre Impact |

| Water Scarcity (gallons) | 106,059.75 | 488,179.29 |

| Abiotic Resource Depletion (MJ eq) | 174,635.41 | 436,944.96 |

| Global Warming (kg Co2) | 15,249.86 | 38,072.72 |

| Eco-toxicity (kg P04 eq) | 11.47 | 31.43 |

We have not included our sustainable cotton corduroy and denim collections as BCI cotton reporting is not available on the Higg MSI tool at this stage. We will look to review this once this data is available.

Definitions:

Water Scarcity

Water is becoming increasingly scarce, due to excessive & unnecessary use and wastage.

Abiotic Resource Depletion

Abiotic depletion refers to the exhaustion of natural (non-living) resources. The main concern is the ecosystem’s health and how it is affected by the extraction of minerals and fossil fuels.

Global Warming (CO2)

Global warming is a serious environmental issue, contributing to the increase in Earth's average surface temperature due to rising levels of greenhouse gases.

Eutrophication (eco toxicity)

Eutrophication is when a body of water becomes overly enriched with minerals and nutrients due to run-off from the land, which causes a dense growth of plant life. This can eventually lead to water bodies that can't support aquatic life.

Abiotic Resource Depletion

Abiotic depletion refers to the exhaustion of natural (non-living) resources. The main concern is the ecosystem’s health and how it is affected by the extraction of minerals and fossil fuels.

| Total fabric left after Fleetwood production = 250m |

We also repurpose our fabric print strike offs from each collection in a collaboration with local brand Zero Waste Kulture to craft our House and Face Wipes. For this quarter, we were able to make a total of 191 Face Wipe packs and 208 House Wipe packs from the print strike offs of our Fleetwood and Flora collections.

If you love fashion and the planet, then what you buy makes a difference.

As a creator of sustainable fashion, it’s our duty to be transparent. Our quarterly sustainability reports disclose our social and environmental policies, practices and impact.

Transparency does not equal sustainability, but

Transparency + Accountability = Change]]>

| What you buy makes a difference |

If you love fashion and the planet, then what you buy makes a difference.

As a creator of sustainable fashion, it’s our duty to be transparent.

Transparency + Accountability = Change

By aligning each section of our Q4 report with the SDG we are actively owning our responsibility to support the achievement of these goals.

Here’s a review of the choices we’ve made in Q4 2020.

| COMMUNITY |

We honour our supplier commitments.

We believe in the importance of strong working relationships and value our supply base.

In Q4 of 2020 as a global community, we are witnessing the impacts of the COVID-19 pandemic as they unfold. With a devastating human toll and an unprecedented shock to the world’s economy, it goes without saying that the fashion industry and supply chains have suffered. Factories have faced order cancellations and suspensions. As a consequence of this many factories are struggling to pay employees, which has led to layoffs and factory closures. This has had devastating ramifications for developing nations, jeopardising basic human needs and food security, as well as the long-term economic impact that has yet to be quantified.

It is our responsibility to honour our commitments both to our makers, and to our sustainability practices and strategy going forward. We have stood in solidarity with our makers and suppliers fulfilling all of our orders placed for this quarter. Social sustainability is about identifying and managing business impacts, both positive and negative, on our people.

However, our makers have faced order cancellations of up to 30% and reductions of up to 80% in comparison to the same time last year

as a result of other brands failing to honour their commitments.

We spoke with our Q4 Makers about how COVID-19 has affected them...

| Bernard - our knitwear Maker. |

| Jason – the Maker of Penny. |

| Joyce – the Maker of Fleetwood Jersey. |

| Rose – the Maker of Fleetwood, Breeze & Esmee. |

| GIVING BACK |

| $45,164.50 |

Find out more about how your donations are being used over on the blog HERE 🌏 & HERE 💚

| Makers |

The fashion industry offers employment opportunities in developing countries, liberating people from poverty.

By committing to regular and consistent orders with our makers we help to ensure job and food security for their workers.

We are committed to using certified fibres and fabrics to ensure the health and well-being of the whole supply chain from the farmers, to the spinners, weavers and makers and ultimately our customers too.

We partner with a supplier that offers education and training to empower disadvantaged women to enter the workforce.

By having a code of conduct in place and auditing our suppliers for social compliance we ensure labour rights are protected and workers have secure working environments.

Through our partnership with makers that have aligned values we strengthen implementation and progress towards the achievement of SDGs.

| FIBRES |

By using organic and BCI cotton fibres we are helping to contribute to more sustainable agricultural practices.

By having a restricted substance list in place, we hope to eliminate exposure to harmful chemicals.

We are committed to using Lenzing fibres as they are extracted from sustainably and responsibly sourced renewable raw wood pulp.

By working with certified mills we aspire to minimise water contamination.

By using organic cotton we are helping to protect soil health and conserve ecosystems.

| Fibres Used in Q4 2020 |

| FIBRE CATEGORIES. |

| FIBRE IMPACT |

| REDUCED FIBRE IMPACT |

| PRINTING & DYING 100% of our fibres were responsibly dyed in Q4 2020. |

Bluesign is a holistic system that provided solutions in sustainable processing and manufacturing, ensuring that products/finished textiles are manufactured with the lowest possible impact on people and the environment.

Oeko Tex 100 = 55%

Oeko Tex 100 certifies that no substances harmful to human health are present in the finished textiles. Substances tested are both regulated and non-regulated going beyond international requirements. Tests are conducted by independent Oeko Tex Partner institutes.

With GOTS all chemical inputs (e.g. dyes, auxiliaries, and process chemicals) must be evaluated and meeting basic requirements on toxicity and biodegradability/eliminability. Prohibition of critical inputs such as toxic heavy metals, formaldehyde, aromatic solvents, functional nano particles, genetically modified organisms (GMO) and their enzymes. The use of synthetic sizing agents is restricted; knitting and weaving oils must not contain heavy metals. Bleaches must be based on oxygen (no chlorine bleaching). Azo dyes that release carcinogenic amine compounds are prohibited

| New Fabrics in Q4 2020. |

Our new Faith intimates are crafted from 66% recycled nylon that is produced from pre-consumer waste, reducing the environmental impact significantly.

As there is a chance of microfibres leaching when washing Faith intimates, we recommend using a Guppy Friend wash-bag to prevent microplastic pollution.

| PLANET SDG’s |

We are committed to reducing our freight carbon emissions by 45% by 2025 in line with the Paris Agreement.

We are committed to being plastic free and only use compostable garment bags and post satchels.

| 100% of our orders were shipped by sea freight in Q4 2020 |

| Compostable bags used/plastic bags saved for the quarter. 10,302 Post Satchels + 15,695 Garment Satchels = 25,997 PLASTIC BAGS SAVED. |

We’re committed to ensuring that our environmental impact is as small as possible & that everyone in our supply chain is respected & cared for.

We’re not perfect & are constantly striving for change.

Throughout this report we have chosen to align each section with the United Nations Sustainable Development Goals.

By aligning each section with the SDG goals we are actively owning our responsibility to help the world achieve these.

Our goal is to create timeless treasures that make you feel powerful & beautiful yet exist in harmony with nature.

Our goal is to create timeless treasures that make you feel powerful & beautiful yet exist in harmony with nature.We’re committed to ensuring that our environmental impact is as small as possible & that everyone in our supply chain is respected & cared for.

We’re not perfect & are constantly striving for change.

Throughout this report we have chosen to align each section with the United Nations Sustainable Development Goals.

By aligning each section with the SDG goals we are actively owning our responsibility to help the world achieve these.

Here’s how we’ve delivered in the past quarter.

MAKERS

SDG’s

1. No poverty

3. Good health and well being

5. Gender equality

8. Decent work and economic growth

10. Reduce inequalities

12. Responsible consumption and production

16. Peace, justice and strong institutions

Our makers are the foundation of globetrottersiraconlineusa, and we take pride in nurturing our existing relationships with our current partners,

JASON

Jason was one of the very first makers found by globetrottersiraconlineusa back in 2012, and we have been working together for nearly 9 years.

During this quarter, Jason meticulously crafted our Leilani, Soleil and Dreamers collections.

| Jason is audited annually by Qualspec. | |

| Collections | Leilani, Dreamers, Soleil |

| Tier One Traceability | |

| Factory Owner | Jason |

| Location | Zeijang, China |

| Auditing Body | Qualspec |

| Audit Rate | Green, No evidence of critical or non compliance |

| Age of Factory | 8 years |

| Youngest Employee | 18 years |

| Gender of Employees | 17 male, 34 female |

| Last audited | 28/6/19 |

| Last globetrottersiraconlineusa Visit | February 2019 |

| Tier 2 Traceability | We have visited both the weaving and print mill. The print mill is a Bluesign systems partner. |

| Tier 3 Traceability | We have visited the yarn mill |

| Tier 4 Traceability | Lenzing certified |

| Tier 5 Traceability | Lenzing certified |

ROSE

Rose was introduced to us two years ago by Jyoti, our Sustainability Coordinator. Rose and her husband have over 30 years of experience in the fashion industry

During this quarter, Rose and her team crafted our best-selling Daisy Chain collection.

| Rose is audited annually by Qualspec. | |

| Collections | Daisy Chain |

| Tier One Traceability | |

| Factory Owner | Rose |

| Location | Shanghai, China |

| Auditing Body | Qualspec |

| Audit Rate | Amber, No critical issues, corrective action plan to be completed |

| Age of Factory | 20 years |

| Youngest Employee | 30 years |

| Gender of Employees | 10 male, 21 female |

| Last audited | 10/4/19 |

| Last globetrottersiraconlineusa Visit | February 2019 |

| Tier 2 Traceability | We have visited the weaving and print mill. The print mill is Oeko Tex 100 certified |

| Tier 3 Traceability | We have visited the yarn mill |

| Tier 4 Traceability | Lenzing certified |

| Tier 5 Traceability | Lenzing certified |

GARIMA

Garima runs a conscious and creative enterprise that is committed to sustainable and ethical manufacturing and takes a holistic approach to people and planet.

During this quarter, Garima’s team crafted our organic cotton Ava collection.

| Garima is audited annually by Sedex. | |

| Collections | Ava |

| Tier One Traceability | |

| Factory Owner | Garima |

| Location | Delhi, India |

| Auditing Body | Sadex - Smeta 3 - Labor, health and safety, environment |

| Audit Rate | 3 pillar |

| Age of Factory | 22 years |

| Youngest Employee | 21 years |

| Gender of Employees | 62 male, 8 female |

| Last audited | 22/11/18 they have been reaudited. Report due in April |

| Last globetrottersiraconlineusa Visit | February 2019 |

| Tier 2 Traceability | GOTS certified |

| Tier 3 Traceability | GOTS certified |

| Tier 4 Traceability | GOTS certified |

| Tier 5 Traceability | GOTS certified |

SHARI

Shari runs a small-scale, sustainable manufacturing unit specialising in hand block printing in Jaipur, India.

Our first ever hand-block printed collection, Lucia, was crafted by Shari at the beginning of this year.

| Collections | Lucia |

| Tier One Traceability | |

| Factory Owner | Shari |

| Location | Jaipur, India |

| Auditing Body | Fairtrade (World Fair-trade Organisation) |

| Audit Rate | NA |

| Age of Factory | 13 years |

| Youngest Employee | 20 years |

| Gender of Employees | 75% male, 25% female |

| Last audited | 1/619 |

| Last globetrottersiraconlineusa Visit | February 2019 |

| Tier 2 Traceability | We have visited the hand block printing artisans. Fair-trade certified |

| Tier 3 Traceability | GOTS certified |

| Tier 4 Traceability | GOTS certified |

| Tier 5 Traceability | GOTS certified |

TRACEABILITY

Our ultimate goal is to have full traceability of our supply chains.

TIERS

Tier 1 – We have 100% traceability of the people making our garments

Tier 2 – We have 75% traceability of where our fabrics are woven, printed and dyed.

Tier 3 – We have 50% traceability of the raw material processing facilities where our yarns are spun from fibres

Tier 4 – We have 0% traceability into where our fibres are are produced

Tier 5 – We have 0% traceability into the where the raw materials that make up our fibres are farmed

We are currently working to map our supply chain beyond Tier 2.

CODE OF CONDUCT

We have a strict code of conduct in place in line with international standards, this is part of our supplier agreement.

SUMMARY OF EURITS:

Fairtrade

Fairtrade supports and empowers marginalised workers, enabling them to build better and more secure lives for themselves and their families.

Qualspec

Qualspec is a globally accredited social compliance audit that meets ISO 9001 standards.

Sedex - SMETA

SMETA is one of the most widely used and recognised ethical audits in the world.

Where were our garments made this quarter?

89% China

11% India

FIBRES

SDG’s

2. Zero hunger

3. Good health and wellbeing

6. Clean water and sanitation

12. Responsible consumption and production

13. Climate action

14. Life below water

15. Life on land

Our fabrics are the result of more than three years of research and development by our production team.

. HEROES .

Lenzing Tencel

TENCEL® fibers are of botanic origin, extracted from sustainably and responsibly sourced renewable raw wood pulp.

Daisy Chain was crafted from Lenzing Tencel.

Revive - Fabric Off-Cuts

Bulk fabric off-cuts and strike offs that would otherwise end up in land fill.

Our Daisy Chain Scrunchies, Leilani Knickers and Lucia beauty bags were crafted from fabric off-cuts.

Lenzing Tencel Modal

TENCEL™ Modal botanical fibres are crafted from responsibly and sustainably grown Beech trees.

Leilani was crafted from Lenzing Tencel Modal.

Lenzing Ecovero

LENZING™ ECOVERO™ branded viscose fibres are of botanic origin, produced in an eco-responsible way

Dreamers was crafted from Lenzing Ecovero,

GOTS/OCS Certified Organic Cotton

Conventional cotton uses large amounts of pesticides, insecticides, herbicides and genetically modified organisms,

Ava and Lucia were crafted from GOTS certified organic cotton

During this quarter, all of the fabrics used in our collections were either:

Heroes – 55% or in our Rising Stars category – 45%.

Fibre Impact vs Reduced Impact

| Fibre Impact | |||||||||

| Fibre Impact | Reduced Impact | ||||||||

| Fiber | Weight kg | CO2 kg | Eco-toxicity kg | Water gallon | Energy MJ | CO2 kg | Eco-toxicity kg | Water gallon | Energy MJ |

| Lining - Tencel | 2774 | 7774 | 5 | 33783 | 122,060 | 131,137 | 10 | 57,452 | 125,808 |

| Organic Cotton | 411 | 489 | 1 | 20,814 | 3,381 | 403 | 3 | 135,605 | 5,938 |

| Main - Ecovero | 635 | 3,297 | 2 | 10,853 | 38,788 | 1,490 | 2 | 10,031 | 17,952 |

| Tencel Modal | 1,180 | 1,513 | 1 | 12,531 | 18,412 | 11,030 | 6 | 23,940 | 122,221 |

Fibre Percentage

| Fibre Percentage | ||

| Fiber | Total Weight Kg | Percentage |

| Organic Cotton | 410.92 | 8 |

| Ecovero | 635 | 13 |

| Tencel | 2,774 | 55 |

| Modal | 1,180 | 24 |

It is now an globetrottersiraconlineusa requirement for all of our makers to have valid environmental certification in place at their mills that print and dye our garments.

During this quarter, 100% of the fabrics used in our collections were responsibly dyed.

See certification breakdown for the quarter below.

Oeko Tex 100

Oeko Tex 100 certifies that no substances harmful to human health are present in the finished textiles.

Bluesign

Bluesign is a holistic system that provided solutions in sustainable processing and manufacturing,

GOTS

All chemical inputs (e.g. dyes, auxiliaries and process chemicals) must be evaluated and meeting basic requirements on toxicity and biodegradability/eliminability.

Prohibition of critical inputs such as toxic heavy metals, formaldehyde, aromatic solvents, functional nano particles,

The use of synthetic sizing agents is restricted; knitting and weaving oils must not contain heavy metals.

Bleaches must be based on oxygen (no chlorine bleaching). Azo dyes that release carcinogenic amine compounds are prohibited.

Azo Free & Low Impact (block printing)

Our block printing is done using azo free low impact inks. The water used in the finishing process is filtered and re-used to minimise water waste

CIRCULARITY

SDG’s

12. Responsible consumption and production

13. Climate action

One of our key focuses over the past two years is how we can ‘close the loop’ both in our production processes and also in the end of the lifecycle of our globetrottersiraconlineusa garments.

We launched our ‘globetrottersiraconlineusa Revive’ initiative at the end of 2018 with the goal of repurposing the fabric that is regarded as waste at the end of the production line of our collections.

Total meters saved from landfill and repurposed into our Revive pieces:

Daisy Chain Scrunchies - 106m

Lucia Revive Bags - 140m

Leilani Knickers - 31.50m

Total = 277.50m (this is approximate as fabric widths vary)

Our next focus will be the end stage of the lifecycle globetrottersiraconlineusa garments and how we can step in to close the loop through a repair and recycling initiative.

COMMUNITY

SDG’s

12. Responsible consumption and production

13. Climate action

14. Life below water

15. Life on land

17. Partnerships for the goals

While most of our production lies offshore with our global network of makers, we have recently shifted our focus locally to collaborate with like-minded sustainable businesses. This past quarter we reached out to a number of brands including Beefolk, Zero Waste Kulture and Kappi to produce zero waste items using fabric off-cuts as part of our Revive initiative. The best part about these collaborations has been providing local seamstresses and artists with a source of work – and in the case of Beefolk and Zero Waste Kulture, right here in the Byron Bay Shire.

Here are our collaborative products launched during this quarter:

Beefolk Beeswax DIY Kits

Beefolk Beeswax Pre-made Wraps

Zero Waste Kulture House Wipes

Zero Waste Kulture Face Wipes

Kappi Reusable Straw Kits

GIVING BACK

As always, we look to support the charities and organisations who are out in our community protecting our oceans, rainforests and native wildlife.

WIRES $30,000

Greenfleet $10,000

Sea Shepherd $5000

Plastic Free July $5000

Tangaroa Blue $5000

Sea Bin $5000

Friends of Koalas $3000

PLANET

SDG’s

12. Responsible consumption and production

13. Climate action

15. Life on land

Packaging

We recognise that crafting our garments from sustainable fibres is only half the battle – we need to package and get our garments to you in materials that won’t further damage our planet. For all paper packaging at globetrottersiraconlineusa, we only use FSC Recycled certified materials.

Wood products carrying the FSC Recycled label have been verified by a third-party certification body as being made from at least 70% post-consumer reclaimed materials, i.e. wood and or wood fibre that has been reclaimed from a product after that product has been used for its intended purpose by individuals or businesses. The remaining material must be verified as pre-consumer waste. Paper products can contain any balance of pre-consumer and post-consumer reclaimed material as long as all applicable parts of the product are verified as reclaimed. The FSC Recycled label does not guarantee that the wood is originally come from FSC certified forests but rather focus on the recycle status and its authenticity.

FSC Recycled packaging used in quarter:

Main Swing Tickets - 11,716

Fabrication Swing Tickets - 11,716

Barcode Stickers - 11,716

Tissue Paper - 11,566

Care Cards - 4500

Shoe Boxes - 200

Shipping Cartons – 140

Compostable bags used/plastic bags saved for the quarter:

Garment Bags – 11,716

Post Satchels – 8,458

Carbon emissions and off-setting

This is how we are contributing to the achievement of these goals:

Greenfleet is a not-for-profit environmental organisation on a mission to protect our climate by restoring our native forests. Using the donations of businesses and individuals, they plant native biodiverse forests which in turn capture millions of tonnes of carbon emissions from our atmosphere, conserve biodiversity, improve water quality, reduce soil erosion and provide vital habitat for native wildlife. At globetrottersiraconlineusa, we have been off-setting our carbon emissions by donating to Greenfleet since 2016.

Carbon off-setting

Charitable donation to Greenfleet

666 tons of carbon dioxide sequestered

2400 trees planted

For this first time ever we have engaged with Carbon Intelligence Pty Limited to create an Independent Greenhouse Gas (GHG) Emissions Verification Statement.

COST

We’re always calculating the cost to our planet when making decisions.

How we’ve evolved:

Approximate cost increase of packaging and trims 49%

Approximate cost increase of printed woven fabrics 20%

Moving to the exclusive use of sustainable fibres from the non-sustainable rayon crepe that we previously used has resulted in increased costs of: